How to Save Money and Time in Testing Fibers with SmartLoop

December 30, 2016 / General, 101 learning, Installation and testing, Upgrading and troubleshooting, Best Practices

The only way to get correct values when performing Tier 2 testing of duplex fiber links with an OTDR is via bidirectional testing that averages the measurements taken from both ends of the link.

Bidirectional testing used to involve testing the fiber from one end, walking the OTDR to the other end to test again and then averaging the two values to get the results—and it had to be done for each link.

Not only did this archaic method of bidirectional testing require more time and labor (not to mention the potential for human error when averaging), sometimes the environment itself makes for an even greater challenge.

Up to the Challenge

Take for example when the other end of the link is difficult to access, or located in a highly secure or unsafe area that could even require special clearance or certifications—exactly what Twistnet Communications Ltd. encountered.

Take for example when the other end of the link is difficult to access, or located in a highly secure or unsafe area that could even require special clearance or certifications—exactly what Twistnet Communications Ltd. encountered.

When Twistnet Communications needed to test upward of 400 fiber links at a wind farm, the remote end was located in a high voltage substation where all the communications and electrical cabling comes together for the power and control of wind turbines.

Working inside the substation required health and safety training and certification at a cost of more than $600 per technician. But Fluke Networks OptiFiber® Pro with SmartLoop™ technology eliminated this setback.

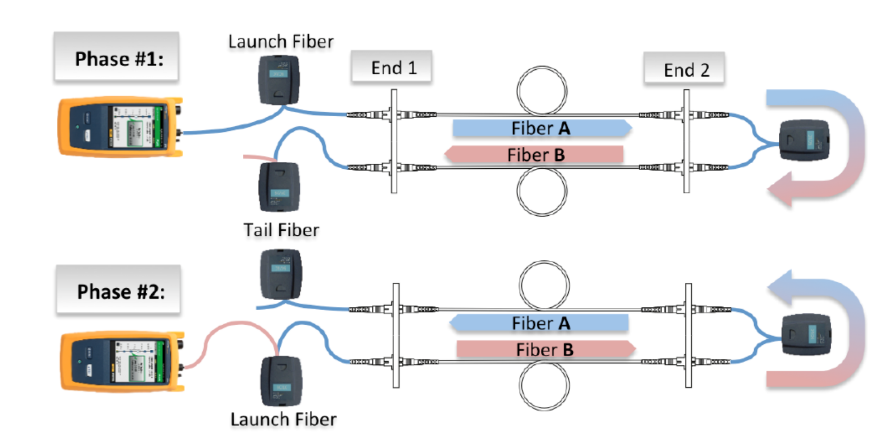

SmartLoop uses a loop at the remote end of a fiber link that allows two fibers of a duplex link to be tested in one shot. In other words, bidirectional testing can be performed without moving the OTDR to the remote end.

Twistnet Communications easily trained one of the safety-certified wind farm personnel to move the remote loop to each link as communicated via walkie-talkie from the technician performing the test.

More Savings, More Jobs

Not only did SmartLoop prevent having to move the OTDR to the other end in an inaccessible area, but it also completely automated the process. The built-in SmartLoop Assistant checks for the presence of the launch, loop and tail fiber when testing a duplex fiber link, and it ensures that both fibers are in the right order and have the expected length.

And when the link test is complete, the SmartLoop Assistant’s results management software automatically reports the bidirectional average for that link, removing any potential for human error to improve accuracy.

All in all, SmartLoop testing saved Twistnet Communications about four days of labor and more than $2500 on the wind farm project. And by cutting testing time by about 50%, SmartLoop technology can help contractors win more jobs—for Twistnet Communications that has meant 20 contracts since using SmartLoop technology!