보증 및 인증 테스트 ROI 실현

2024년 4월 6일 / 일반, 설치 및 테스트, 모범 사례

One could argue that certification testing of an installed structured cabling plant is optional and time consuming. But if an end user wants a system warranty, “optional” is the last word to describe this crucial step. As Panduit’s product line manager Frank Straka put it, “Certification testing will always be required for warranty, regardless of the number of drops on a project.”

And it’s not just a Panduit requirement — all reputable cabling system manufacturers require certification testing for the end user to obtain a system warranty. Let’s explore how certification supports manufacturer guarantees of ROI on structured cabling.

The value of cabling system warranty

While a structured cabling plant is typically only about 15% of the cost of total network deployment, it’s essential for connecting people and devices and transmitting information. It also happens to be the most challenging and expensive part of the network to replace, requiring extensive labor and significant disruption to a workplace. Therefore, the structured cable plant should have the longest lifecycle.

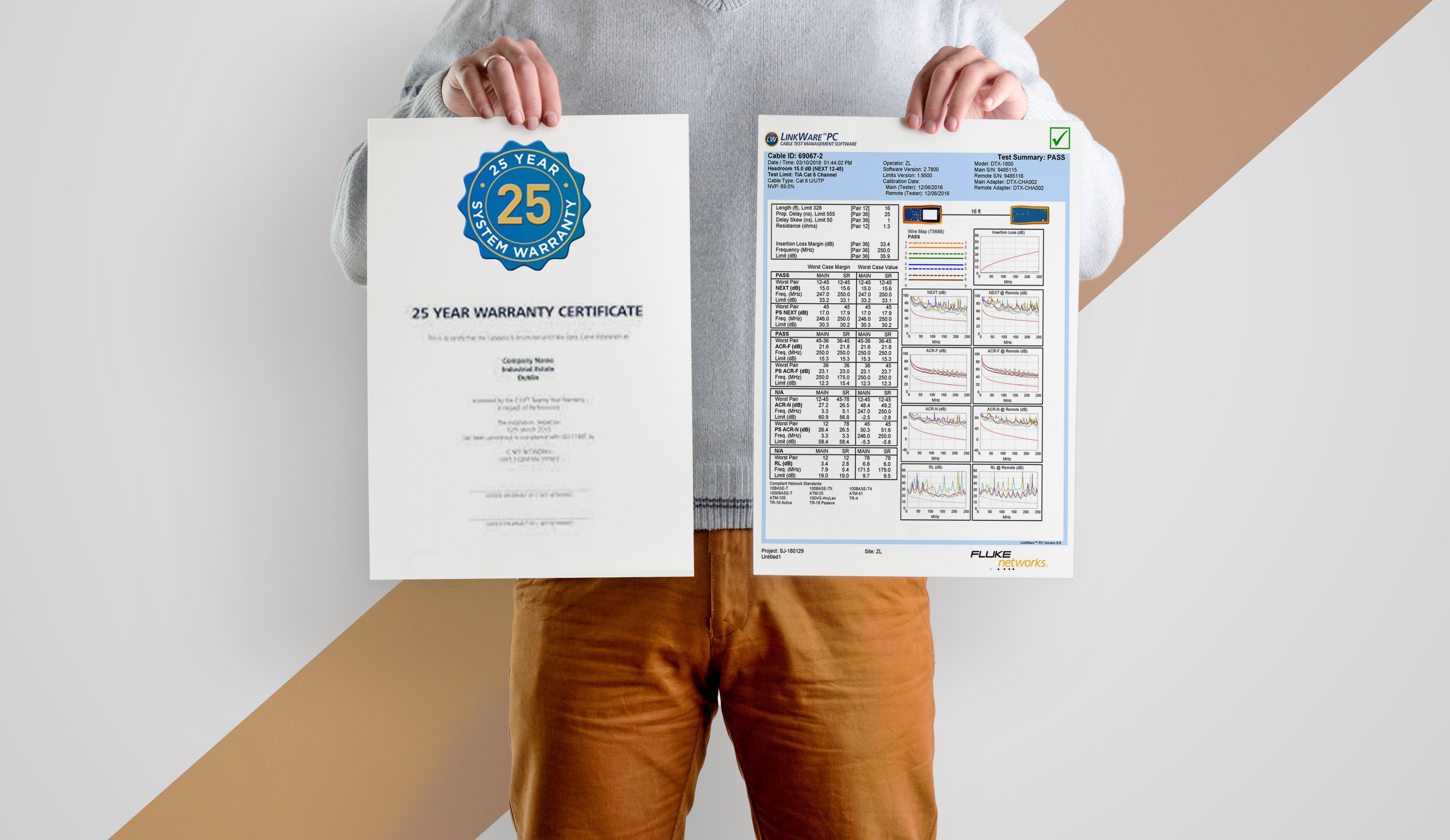

Leading cabling system manufacturers offer product warranties that cover individual components against defects. These warranties range from 1 to 5 years, depending on the product. But it’s the system warranty that ensures performance over the lifecycle of the structured cabling plant. Sometimes called an “extended” warranty or application assurance, a system warranty guarantees that the structured cabling plant will support current and future applications designed to run on that system.

“The structured cabling system is the foundation of the network and the most disruptive component to replace. We want our customers to get the most out of their investment and support multiple generations of equipment and applications,” says Dave Valentukonis, North American technical services manager for Siemon. “A system warranty adds a layer of assurance for our customers. It also protects and strengthens our relationship with certified installers, who are an extension of our brand and vital to maintaining our industry reputation for innovative, high-quality, high-performance cabling and connectivity.”

Most system warranties from leading industry manufacturers last for 20 or 25 years. Significant value lies in the fact that an end user doesn’t have to worry about the ability of the structured cabling system to outlast several generations of network equipment. For installers, offering a system warranty sets them apart from the competition, demonstrates their commitment and expertise, and gives customers peace of mind to keep them coming back.

No warranty without certification testing

Manufacturers don’t hand out cabling system warranties to just anyone. They require Bill of Materials (BOM) proof that every component was theirs, and most necessitate installation by one of their certified installers. Many even require installers to be BICSI certified, with a Registered Communications Distribution Designer (RCDD®) on staff. But the number one requirement to obtain a system warranty is certification testing.

“Certification testing will always be required for warranty, regardless of the number of drops on a project.” – Frank Straka, Panduit

Belden, CommScope, Corning, Hubbell, Leviton, nCompass (Superior Essex and Legrand), Paige, PanGen (Panduit and General Cable), Siemon, and Signamax system warranties all require certification testing. In fact, end users, designers, and installers alike should be wary of any cabling system manufacturer that doesn’t offer a warranty AND require certification testing — it’s a sure red flag of sub-standard, non-compliant, or even counterfeit components, which opens a whole new area of risk.

“We require 100% certification testing as objective evidence that our products and systems were installed properly, which is critical for Siemon to offer a 25-year performance and application warranty,” asserts Valentukonis.

One-hundred-percent certification testing means that once installed, every link must be tested to ensure compliance with a specific category or Class of cable, as determined by parameters and channel limits outlined in ANSI/TIA-568 or ISO/IEC 11801 cabling standards.

- • For copper twisted-pair category cabling, we’re talking about insertion loss, return loss, and crosstalk parameters like near-end crosstalk (NEXT), power sum NEXT, equal-level far-end crosstalk (ELFEXT), attenuation-to-crosstalk ratio (ACR), and alien crosstalk (ANEXT).

- • For fiber, it means testing for continuity, polarity, length, insertion loss (Tier 1 certification), backscatter, reflectance, and optical return loss (Tier 2 certification).

There are some exemptions — certification testing is often not required for pre-terminated cabling systems that are pre-tested at the factory. Some manufacturers also don’t require alien crosstalk testing for Category 6A copper cabling, and most only require Tier 1 testing for fiber systems, rather than Tier 2.

Why do manufacturers require certification testing?

“There are many ways a cable plant installation can go bad — shipping damage, water or paint getting onto the cable, job site conflicts, inexperienced installers, and more,” Panduit’s Straka explains. “Certification testing protects our end users, Panduit ONE partners, and Panduit. End users know that they received the system that they wanted. Panduit ONE partners can leave a job site knowing that the product they installed worked, and if they get a call on a bad link, they have a record of the performance when they left. And Panduit knows that the installation was initially done properly.”

Ron Tellas, Belden’s technology and applications manager for LANs, points out that warranty programs and certification testing also ensure ROI for certified training programs that comprise a substantial percentage of manufacturers’ expenses. In addition to trainer salaries, these programs include training facilities, materials, travel expenses, administration, and other operational costs. “Certification testing helps us justify the use of certified installers — it’s also something we can attach to good installers and vice versa.”

There’s also value in choosing the right certification tester. Manufacturers provide a list of approved testers — where you’re almost guaranteed to see a Fluke Networks Versiv™ Cable Certifier. With the highest accuracy level and graphical displays showing exactly where any failures are on a given link, Versiv helps installers and manufacturers identify and address the cause of any problems early in the process.

“Requiring tests from a Fluke certification tester in the native .FLW format has allowed us, on multiple occasions, to identify the root cause of marginal or failing links,” says Siemon’s Valentukonis. “Having the ability to review these tests remotely and provide quick feedback saves us time and travel, keeps our customers on schedule, and saves our installation partners time and money.”

There will always be the potential for situations where an end user doesn’t care about a system warranty and doesn’t want to pay for certification testing, even though the labor to perform and document the testing adds only about 5% to a typical installation job. But regardless of the end user’s specification, installers should still do certification testing even at their own expense. It’s insurance that protects them from product failures and provides proof that work was done correctly — and it can prevent them from being on the hook for repairs and replacements later.